siebenundvierzig.

YES! It just goes to prove that if you (a) read the directions and (b) follow the directions, good things generally happen. We're casting plaster molds in studio right now. And most people are just half-hazardly guessing the parts of water they need to parts of plaster and then carelessly pouring into their mold.The problems here are:

(a) The molds take an hour or more to make (depending on your level of craft)

(b) The molds are not reuseable once poured into

(c) Wasting materials

(d) Stupidity

Seriously, people might as well just use play-doh to make their models if they are going to go about it like a kid smashing shapes out of the favorite childhood pastime material.

Okay, off my soapbox, I'm really proud (and simultaneously relieved) that I will be able to pour with the confidence of getting my desired results in one shot! Bomb biggity! Pictures of my final models to follow once all my molds are cast and cleaned. :o) (It's all due Monday, so hopefully I'll have stuff up by the end of that day, but you can see my test casts below.)

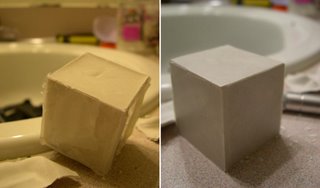

#01: Plaster cast in a foam core mold. As you can see, the black foam core left residue and it was still a little bit damp when I broke it out of the mold one hour after pouring.

#02: Plaster cast in a plexiglass mold. This was WAY cool. The edges are crisp, clean, and shiny - reminding me of the glossy finish associated with marble.

2 Comments:

Hope you were able to make this work for today!!!

Yeah, I need to post more pictures... things are just so busy!

Post a Comment

<< Home